- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: maanshan

- Brand Name: jiahe

- Model Number: finishing die

Mould material: Cold Work Die Steel

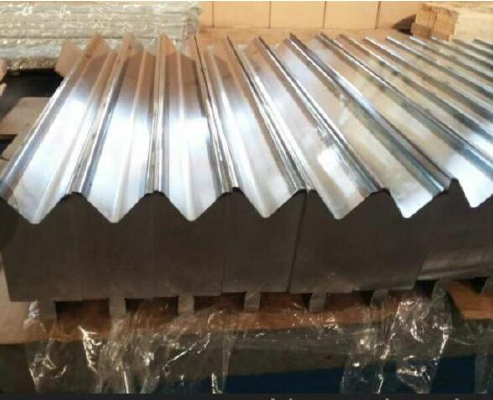

Mold type: forming die

Mold performance: bending

Mold purpose: bending

Mold design software: AutoCAD

Mold processing: grinding

Surface treatment: laser heat treatment

Mold parts processing: precision grinding

Proofing cycle: 4-7 days

Processing cycle: 8-15 days

100MM:800MM

He mainly to undertake the manufacture of various types of precision mold design, specializing in a variety of bending mold, high precision stamping die; mold. Is precision tools, complex shape, bearing blank expansion force of structure strength, stiffness, surface hardness, surface roughness and machining accuracy have higher requirements, Jiahe has advanced equipment, mirror the polishing process and advanced heat treatment technology, such as laser heat treatment, the surface hardness of mould lifting% 30%, the quality of machined workpiece mold, high precision, but also reduces the number of grinding repair mould. The products are widely used in automotive, electronics, communications, home appliances, medical, sheet metal processing, elevator manufacturing industry. Automation and other areas. Non standard products can be customized according to customer demand, proofing.

Bending die for forming: sheet metal processing tool, this tool has a variety of parts, different from different parts of the mold processing. It is mainly through the molding material physical state changes to achieve the object shape. Used in pressure bending machine under the blank into a specific shape and size of the parts tool material: imported materials, T8, T10,42CrMo etc.

- Place of Origin: maanshan

- Brand Name: jiahe

- Model Number: finishing die

Mould material: Cold Work Die Steel

Mold type: forming die

Mold performance: bending

Mold purpose: bending

Mold design software: AutoCAD

Mold processing: grinding

Surface treatment: laser heat treatment

Mold parts processing: precision grinding

Proofing cycle: 4-7 days

Processing cycle: 8-15 days

100MM:800MM

He mainly to undertake the manufacture of various types of precision mold design, specializing in a variety of bending mold, high precision stamping die; mold. Is precision tools, complex shape, bearing blank expansion force of structure strength, stiffness, surface hardness, surface roughness and machining accuracy have higher requirements, Jiahe has advanced equipment, mirror the polishing process and advanced heat treatment technology, such as laser heat treatment, the surface hardness of mould lifting% 30%, the quality of machined workpiece mold, high precision, but also reduces the number of grinding repair mould. The products are widely used in automotive, electronics, communications, home appliances, medical, sheet metal processing, elevator manufacturing industry. Automation and other areas. Non standard products can be customized according to customer demand, proofing.

Bending die for forming: sheet metal processing tool, this tool has a variety of parts, different from different parts of the mold processing. It is mainly through the molding material physical state changes to achieve the object shape. Used in pressure bending machine under the blank into a specific shape and size of the parts tool material: imported materials, T8, T10,42CrMo etc.